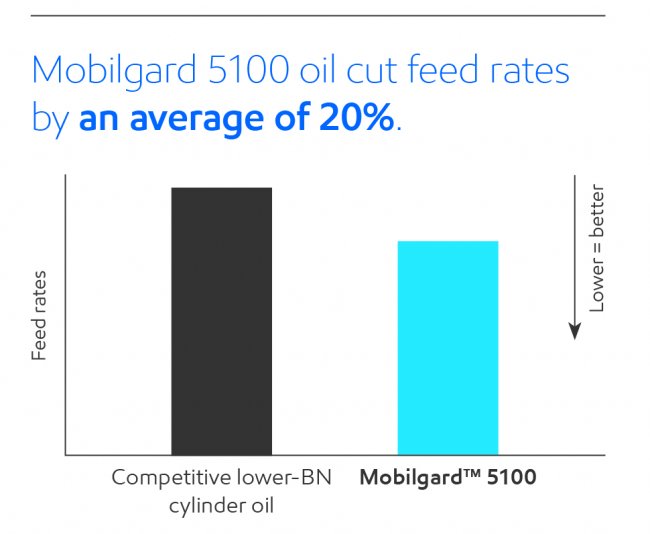

Vessels tackled cold corrosion, cut feed rates by 20%

Tuesday, 17/03/2020, 10:38 GMT+7

| Nanjing Kingship Management mitigated severe cold corrosion in Wärtsilä 6RT-Flex48T engines by switching to Mobilgard™ 5100 oil. Importantly, during challenging marine industry conditions, MobilGard™ CCM showed potential to reduce cylinder oil feed rates, leading to an annual saving of USD $42,000. |

Situation

Nanjing Kingship Management was striving to optimise operations and reduce costs in the face of falling freight rates. Severe cold corrosion in four vessels threatened to trigger engine overhauls and downtime. The Wärtsilä 6RT-Flex 48T engines used fuels with sulphur levels of between 2.8 to 3.2 percent at an average engine load of 70 percent. Wärtsilä Pulse Lubricating Systems were operating at a high level — around 1.2-1.3g/KWh.

Recommendation

The technical team at Nanjing Kingship Management worked closely with ExxonMobil engineers and agreed to implement the MobilGard Cylinder Condition Monitoring (CCM) programme across all four vessels. This enabled an assessment of the scale of the cold corrosion problem. The engineers also advocated a switch to Mobilgard 5100, a 100 BN cylinder oil, in line with guidance from Winterthur Gas & Diesel Ltd. Mobilgard 5100 oil can be a more cost-effective lubricant for engines suffering from cold corrosion than a lower-BN oil at a high feed rate.

Impact

Information from the MobilGard CCM programme showed that following the switch to Mobilgard 5100 oil, it was possible to end cold corrosion while also achieving a 20 percent cut in feed rates. The vessel operator additionally reported enhanced engine reliability as a result of putting an end to abnormal wear, and extended overhaul intervals, which helped reduce overall operating cost.

Your Comments